Leak Testing

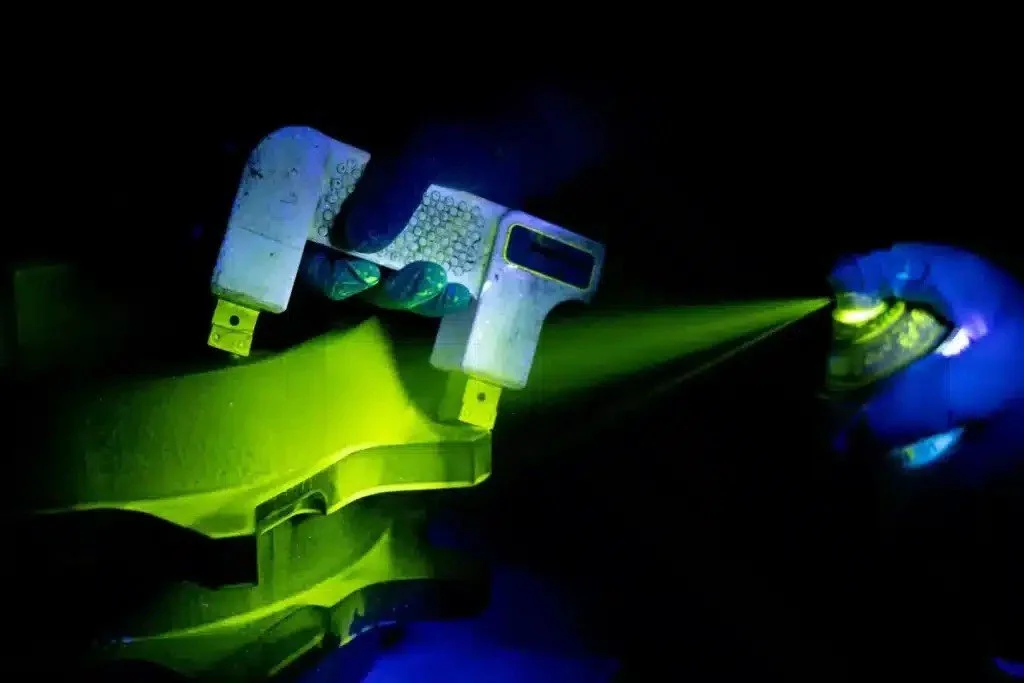

Leak Testing (LT) is a non-destructive testing (NDT) method used to detect and locate leaks in sealed systems, pipelines, pressure vessels, and other components without causing damage. It involves introducing a test medium (gas, liquid, or tracer substance), applying pressure or vacuum, and monitoring for leakage indicators.